Factory Lighting Case Study

About this project

Our client, a UK based food manufacturer operating on an international scale, operates factory facilities which employ hundreds of people. Due to the nature of our client’s business, the existing lighting was switched off on Christmas Day. The existing lighting systems in the factory had become very dated and expensive to run.

Key Issues:

- To Retain or enhance the existing light levels

- To maximise the energy savings

- To minimise the maintenance cost of the lighting

The 3E Solution

As lighting system specialists with years of expertise and experience in providing solutions to clients in both the private and public sectors. We worked with the client in developing a new lighting installation that exceeded the brief suggested by the client.

Our approach included:

- A complete survey of the lighting system originally in place

- Use of our in-house photometric laboratory to utilise our extensive range of bespoke luminaires and control systems to design a custom system, bespoke to the exact specification and requirement of the client.

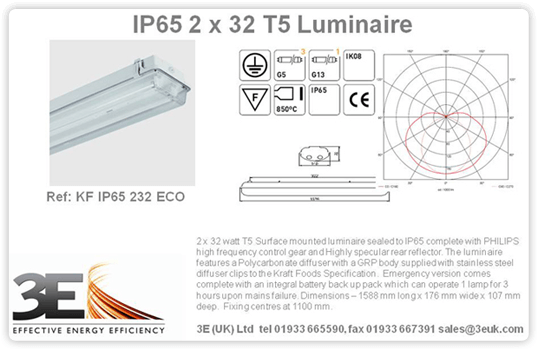

In 2010, we replaced the existing 270 five-foot twin lamp fittings with an equal number of our T5 ECO luminaires. The T5 luminaires delivered the expected results to the client; these being reduced costs and improved performance and economic efficiency.

10 years later, with further advances in technology and product availability, we showcased our newer, more refined 3E LED luminaires to the client. The improvements provided by our 2020 custom luminaire system was deemed by the client to outweigh the cost of implementing it into their production facility.

The Outcome

In 2010, the replacement of the existing five-foot twin lamp lighting system with our T5 ECO Luminaries resulted in the following results:

- A lighting energy consumption reduction by 52%

- An installed load road reduction of 20kW

These significant benefits provided by the 2010 system we fitted allowed for a payback period of only 1.2 years.

With the 2020 3E LED luminaire upgrade to our original system, the following results were obtained, paying themselves back in energy savings within 2 years:

- A further energy consumption reduction of 46%. (A 76% overall reduction from the pre-2010 energy consumption value).

- Another 8.56kW reduction in installed load.

The 2020 system also provides a far more eco-friendly and environmentally sustainable option in comparison to its predecessors.

Results

| Data | Before | After | Saving |

| No. of Fittings | 379 | 320 | -59 |

| Installed Load | 53.82kW | 21.76kW | -23.06kW p.a. |

| Light Level | >300 lux | 440 lux | +46% |

| Cost | £51,700 p.a. | £19,800 p.a. | £31,900 p.a. |

| PAYBACK Installed | 1.56 years |

Energy Saving = 60%

In Summary

We were approached by an international food manufacturing company to replace their existing lighting systems and subsequently upgrade their efficiency, reliability, and overall performance; whilst simultaneously reducing their lighting related costs and maintenance requirements.